In daily life, we often come into contact with a variety of packaging materials, such as paper boxes, plastic boxes, glass bottles, etc. However, there is another packaging material that has attracted much attention due to its unique characteristics and wide range of applications, and that is the Tin Box.

This article will introduce in detail what a tin box is, the history of tin boxes, the manufacturing process, the advantages of tin boxes, and their applications in various industries.

What is a Tin Box?

A tin box refers to a box made of tin material, which is usually used to package food, gifts, cosmetics, medicines, etc. Although we call it a "tin box", in fact, this material is not entirely tin, but tin-plated steel sheet. Tin-plated steel sheet is a thin layer of tin covered on the surface of the steel sheet, which can provide the strength and rigidity of steel and take advantage of the anti-corrosion properties of tin. Tin boxes usually have excellent sealing and moisture-proof properties, which makes it an ideal choice for packaging many products.

History of Tin Boxes:

The history of tin boxes can be traced back to the early 19th century. At that time, European countries began to use tin-plated steel sheets to make food packaging boxes to extend the shelf life of food. With the development of the industrial revolution, tin plating technology has gradually matured, and the production of tin boxes has become more popular. In the early 20th century, tin boxes began to be widely used worldwide, especially in the food and confectionery industries.

In China, the use of tin boxes also has a long history. Since the 1930s, with the development of the canning industry, tin boxes have gradually been used for the packaging of various foods and daily necessities. Today, with the continuous advancement of technology and the enhancement of environmental awareness, the application fields of tin boxes are becoming more and more extensive, and the market demand is also growing.

What is the manufacturing process of tin boxes?

The manufacturing process of tin boxes is relatively complicated and requires multiple processes, mainly including the following steps:

Raw material selection

The main raw material of tin boxes is tin-plated thin steel sheet. Tin-plated thin steel sheet is made of high-quality low-carbon steel sheet, which is pickled, annealed and cold-rolled before tinning. The tinning process usually uses electroplating or hot-dip tinning to evenly cover the surface of the steel sheet with a thin layer of tin to enhance its corrosion resistance and aesthetics.

2. Cutting and forming

The tin-plated steel sheet is cut according to the size of the design drawing to form the various parts of the tin box. The cut steel sheet needs to be stamped and bent to form components such as the box body, box cover and bottom plate. This step requires the use of precision molds and mechanical equipment to ensure that the size and shape of each component are accurate.

3. Printing and coating

In order to improve the beauty and brand recognition of the tin box, printing and coating are usually performed on the surface of the steel sheet. The printing process uses high-quality inks and advanced printing equipment to achieve exquisite patterns and texts. The coating treatment is to increase the wear resistance and glossiness of the surface. Commonly used coating materials include transparent paint, matte paint and varnish.

4. Assembly and welding

Assemble and weld the various components according to the design requirements to form a complete tin box. The assembly process requires strict control of the tightness and sealing of each connection to ensure the moisture-proof performance and strength of the tin box. The main welding processes include resistance welding, laser welding and ultrasonic welding. The specific process to be selected depends on the shape and usage scenario of the tin box.

5. Inspection and packaging

The finished tin boxes need to undergo strict quality inspection to ensure that each product meets national and industry standards. The inspection content includes dimensional accuracy, printing quality, sealing performance and appearance defects. Qualified tin boxes will be packaged and shipped according to the order requirements and delivered to customers.

What are the advantages of tin boxes?

The reason why tin boxes are so popular is mainly because they have the following significant advantages:

Anti-corrosion performance

Tin has good corrosion resistance and can effectively prevent the erosion of air, moisture and chemicals on the contents of the package. This makes tin boxes very suitable for packaging products with high hygiene requirements such as food, medicine and cosmetics.

High strength and durability

Tin-plated thin steel sheets not only have the corrosion resistance of tin, but also the strength and rigidity of steel. This makes tin boxes more durable than packaging boxes made of other materials and can effectively protect the contents during transportation and storage.

Good sealing performance

Tin boxes are usually designed with tight lids and closed structures, which can provide excellent sealing performance, prevent the entry of air and moisture, and thus extend the shelf life of the contents.

Recyclability and environmental protection

Tin boxes are a recyclable packaging material that can reduce resource waste and environmental pollution. In the current context of increasing environmental awareness, the recyclability of tin boxes is undoubtedly one of its important advantages.

Beauty and diversity

The surface of the tin box can be beautifully printed and coated, with high decorative and brand display effects. In addition, tin boxes can be designed into various shapes and sizes according to customer needs to meet the packaging needs of different products.

Application of tin boxes in various industries

Due to their unique advantages, tin boxes are widely used in various industries, mainly including the following aspects:

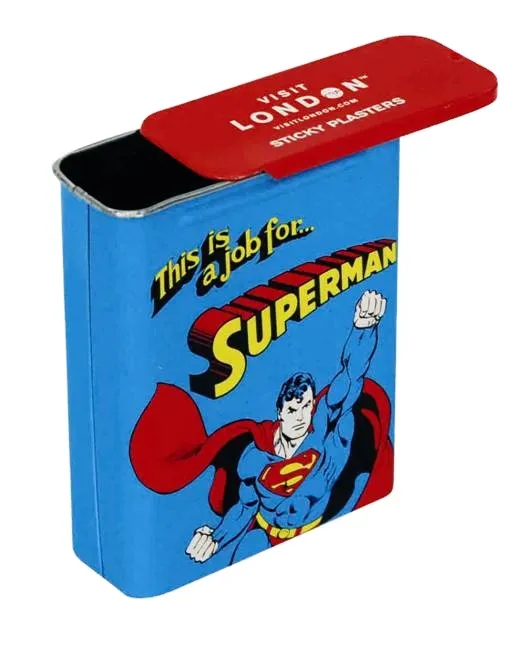

Food industry

The food industry is one of the most widely used areas for tin boxes. Tin boxes are often used to package foods such as biscuits, candies, tea, coffee and chocolate. They can not only effectively maintain the freshness and taste of food, but also have a good display effect. In addition, many high-end food gift boxes also use tin box packaging to enhance the grade and added value of the product.

Cosmetics industry

The cosmetics industry has very strict requirements on packaging materials, which must not only ensure the safety and stability of the product, but also have a high-end appearance and texture. Tin boxes are an ideal choice for cosmetic packaging due to their corrosion resistance and aesthetics. Many cosmetic brands choose to use tin boxes to package perfumes, creams, lipsticks and other products to highlight their high-end quality.

Pharmaceutical industry

The pharmaceutical industry has extremely high requirements for the hygiene and safety of packaging materials. Tin boxes are widely used in pharmaceutical packaging due to their excellent sealing performance and corrosion resistance, especially for some medicines that need to be preserved for a long time, such as Chinese medicine pills, plasters and nutritional supplements.

Gift and craft industry

The beauty and designability of tin boxes make them a popular choice for gift and craft packaging. Whether it is a holiday gift, souvenir, or artwork, tin boxes can add a touch of sophistication and elegance to it. In addition, many brands will print unique patterns and logos on tin boxes to enhance their brand image and market competitiveness.

Electronic products industry

The electronic products industry has also begun to gradually adopt tin boxes as packaging materials. The high strength and moisture resistance of tin boxes can effectively protect electronic components and equipment from the influence of the external environment. Many high-end electronic products, such as headphones, smart watches, and small electrical appliances, choose tin box packaging to enhance the added value of the product and user experience.