In the modern packaging industry, Tin Packaging has become an indispensable form of packaging due to its excellent protective performance and wide application fields. Whether it is food, beverages, cosmetics, or chemical products and gift packaging, tin cans have occupied a place in the market with their unique advantages.

So, what is Tin Packaging? This article will analyze in detail the definition, history, manufacturing process, application fields and advantages of Tin Packaging.

What is Tin Packaging?

Tin Packaging, as the name suggests, is a packaging container made of iron as the main material. Tin cans are mainly made of tin-plated iron (also known as tinplate), and their anti-corrosion properties are improved by plating a layer of tin on the surface of the iron plate. The sealing performance of the tin can is excellent, which can effectively protect the contents from the influence of the external environment, thereby extending the shelf life and service life of the product.

History of Tin Packaging:

The history of tin can packaging can be traced back to the early 19th century. In 1810, British businessman Peter Durand first obtained a patent for tin can packaging. Since then, iron cans have been quickly used in food storage and transportation, providing a convenient way of food supply for the army at that time. With the continuous advancement of technology, the production process and materials of iron can packaging have also been significantly improved, and gradually become an important part of the modern packaging industry.

What is the manufacturing process of iron can packaging?

The manufacturing process of iron can packaging is relatively complicated and involves multiple links. The following are the main manufacturing steps of iron can packaging:

Material preparation

The main material of iron cans is tinplate, that is, a layer of tin is plated on the surface of the iron plate to enhance its corrosion resistance. The thickness and quality of tinplate directly affect the performance and appearance of the iron can, so strict control is required when selecting materials.

Shearing and forming

The tinplate plate is cut into suitable sizes by a shearing machine and then sent to a punching machine for forming. The punching machine presses the iron plate into the preliminary shape of the can body, including the can body, can bottom and can lid.

Welding and sealing

The formed can body needs to be welded to ensure its sealing performance. The welding process usually uses resistance welding or high-frequency welding to firmly connect the seams of the can body. The bottom and lid of the can are connected to the can body through crimping or pressing process to form a sealed structure.

Surface treatment

In order to improve the aesthetics and protective performance of the iron can, the surface of the can body usually needs to be painted or printed. Surface treatment can not only enhance the corrosion resistance of the can body, but also provide a good visual effect for the product.

Inspection and packaging

After manufacturing, the iron can needs to undergo strict quality inspection, including inspection of sealing, pressure resistance and appearance quality. Qualified iron cans are finally packaged as finished products and ready to leave the factory.

What are the application areas of iron can packaging?

Iron can packaging is widely used in many fields due to its excellent protective performance and diversified design. The following are the main application areas of iron can packaging:

Food packaging

Food packaging is one of the most common application areas of iron cans. Iron can packaging can effectively isolate air and light, prevent food from moisture, oxidation and deterioration, and extend the shelf life of food. Common food cans include canned food, candy cans, biscuit cans, etc.

Beverage packaging

Iron can packaging has also been widely used in the beverage industry, especially in the packaging of beer and carbonated beverages. The sealing and pressure resistance of tin cans can maintain the taste and bubbles of beverages while avoiding external contamination.

Cosmetic packaging

Iron can packaging is also popular in the cosmetics industry, especially for the packaging of high-end skin care products and perfumes. The elegant appearance and good protective performance of tin cans make it an ideal packaging choice for high-end cosmetics.

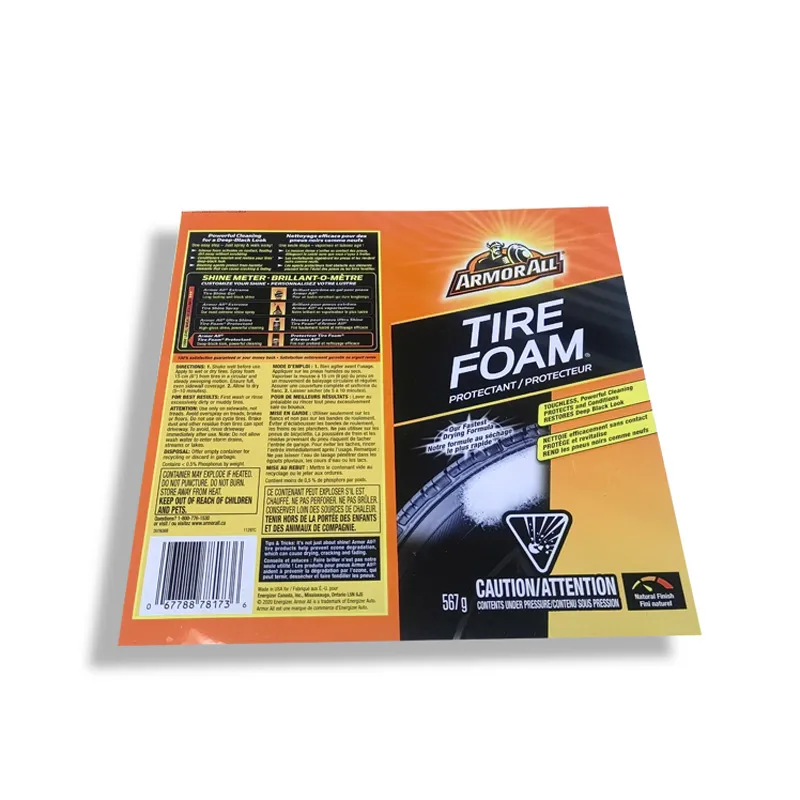

Chemical product packaging

Iron can packaging is also widely used in the packaging of chemical products, such as paints, solvents and lubricants. The anti-corrosion and sealing properties of tin cans can effectively prevent the leakage and deterioration of chemicals, ensuring the safety and stability of products.

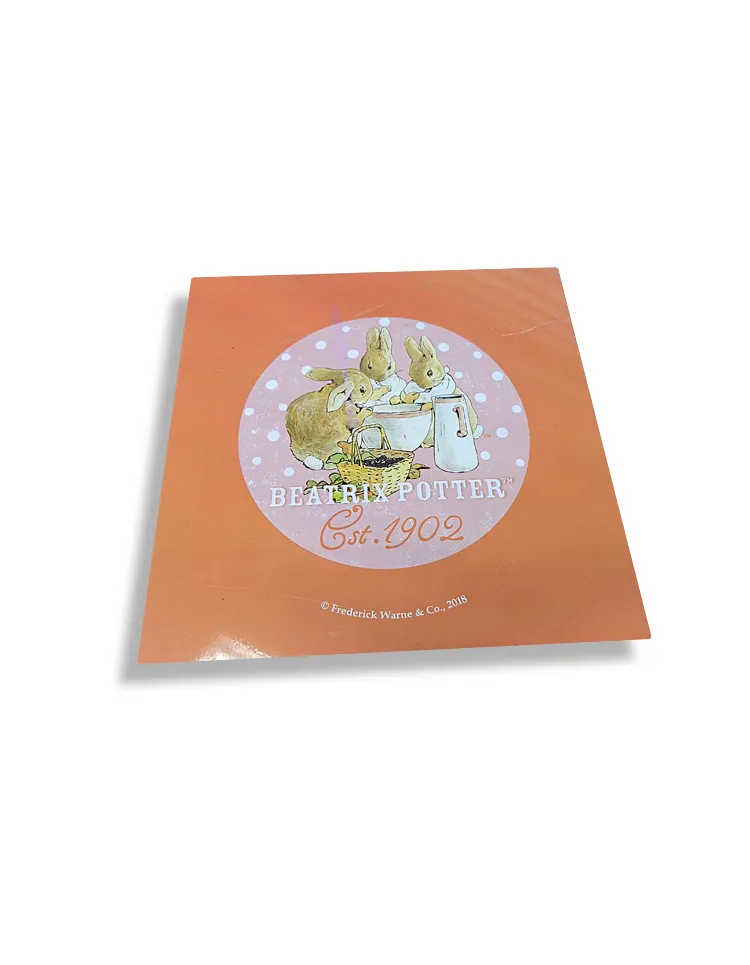

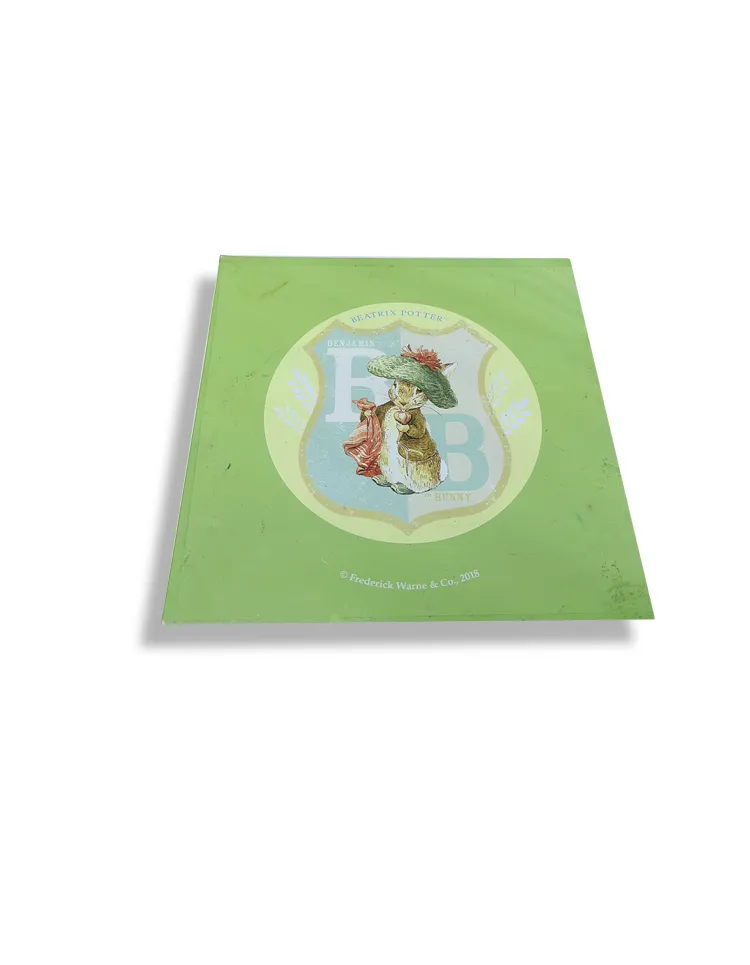

Gift packaging

The diverse design and exquisite appearance of tin cans have also occupied a place in gift packaging. Tin cans can be customized according to different types of gifts to enhance the grade and beauty of gifts.

What are the advantages of tin can packaging?

Tin can packaging stands out among many packaging materials, mainly due to its unique advantages. The following are the main advantages of tin can packaging:

Excellent protective performance

The sealing and anti-corrosion properties of tin cans enable it to effectively isolate the influence of the external environment on the contents and extend the shelf life and service life of the product. Whether it is food, beverages or cosmetics, tin cans can provide good protection.

High strength and durability

Iron cans have high mechanical strength and durability, and can withstand the impact and pressure that may be suffered during transportation and storage, preventing the contents from being damaged. This makes tin can packaging have significant advantages in transportation and storage.

Elegant appearance

The surface of the tin can can be treated with a variety of coatings and printings, presenting a beautiful appearance design. This makes the tin can packaging highly attractive in marketing and can enhance the brand image and market competitiveness of the product.

Environmental protection

Iron cans are an environmentally friendly packaging material. Tinplate can be recycled and reused, reducing resource waste and environmental pollution. Compared with other disposable packaging materials, the environmental protection performance of tin cans is significant.

Diverse designs

The plasticity and processing technology of tin cans enable them to be designed and customized in a variety of ways according to the needs of different products. Whether it is shape, size or surface pattern, tin cans can meet different packaging needs.