As an important packaging material, tin plate is widely used in food, beverage, chemical products, daily necessities and other industries. Its excellent corrosion resistance, mechanical strength and sealing performance make it an ideal choice for packaging of various commodities. However, many people do not know much about the shelf life of tinplate products. The shelf life of tinplate products does not only depend on the material itself, but also on many factors such as the use environment, coating protection, the characteristics of the contents and storage conditions.

This article will deeply analyze the key factors affecting the shelf life of tinplate products from the aspects of material characteristics, manufacturing process, use environment, protective coating, etc., and give a detailed answer to the question of "How long is the shelf life of tinplate products".

What are the basic material properties of tinplate?

To discuss the shelf life of tinplate products, we first need to understand the basic properties of tin plate. Tin plate is a metal material made of tin-plated thin steel plate. Its core component is steel, and the surface is coated with a layer of tin to enhance the corrosion resistance of the material.

Durability of steel substrate

The core of tin plate is steel, which has strong mechanical properties and can withstand certain pressure, impact and deformation. This makes tinplate products have good strength and toughness during use, and will not be easily damaged by external physical impact or extrusion under normal circumstances. In addition, the molecular structure of steel materials is very stable and is not easy to deteriorate or change structure at room temperature, so its basic physical properties can be maintained for a long time.

Anti-corrosion effect of tin layer

The surface of tinplate is coated with a thin layer of tin. The main function of this layer of tin is to prevent the steel substrate from direct contact with air, moisture and other corrosive substances, thereby preventing rust. Tin has good corrosion resistance and can greatly extend the service life of tinplate products. However, the thickness and uniformity of the tin layer have a great influence on its protective effect. If the tin layer is thin or uneven, it may lose its protective function in some areas, thereby accelerating the corrosion process of the substrate.

What effect does the manufacturing process of tinplate products have on the shelf life?

The shelf life of tinplate products depends not only on the characteristics of the material itself, but also on the production and manufacturing process. Different process will directly affect the durability and protection of tinplate products.

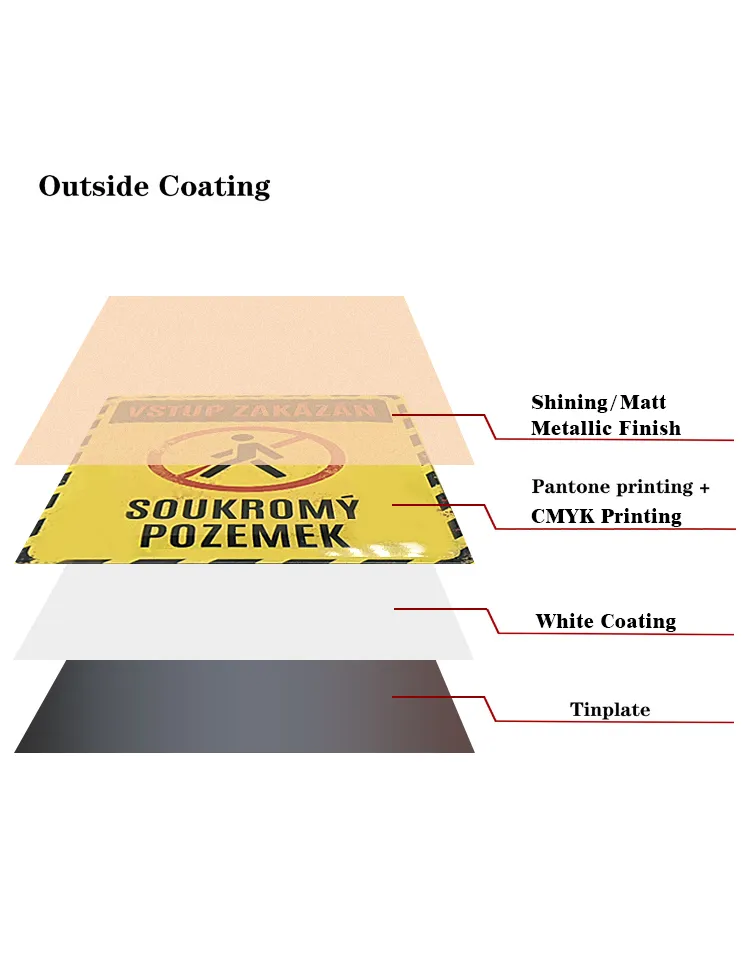

Coating process

Tinplate products are usually surface coated during the manufacturing process to further enhance their corrosion resistance. Common coatings include epoxy resin, polyester and other organic coatings. These coatings can provide an additional protective barrier for tin plate, preventing air, moisture and acidic and alkaline substances in the contents from directly contacting the metal, thereby extending the service life of the product.

In the coating process, the thickness and uniformity of the coating are crucial. If the coating is uneven or defective, the metal under the coating may be exposed to the corrosive environment, which will affect the shelf life of the entire tinplate product. Therefore, the control of the coating process has a direct impact on the quality of the product.

Welding and seaming process

The manufacturing process of tinplate products usually requires welding or seaming processes. For example, in the production of cans and chemical barrels, the closure and firmness of the can body have an important impact on the shelf life of the product. If these welding or seam parts are not handled properly, they will become weak links for corrosion, which may cause external air or liquid to penetrate, thus affecting the material safety inside the product and the overall durability of the can.

In modern processes, the use of lead-free welding or high-precision automatic welding technology can effectively reduce defects in the welding area, improve the sealing and durability of tinplate products, and thus extend their shelf life.

What is the impact of the use environment on the shelf life of tinplate products?

In addition to the material itself and the manufacturing process, the use environment of tinplate products is also an important factor in determining the length of its shelf life. Different use environments will directly affect the corrosion resistance of tin plate, thereby changing its life.

Humidity and temperature

Humidity and temperature are two key environmental factors that affect the corrosion rate of tinplate products. In a high humidity environment, moisture in the air will accelerate the oxidation process of the tin layer. If the coating or tin layer is damaged and the steel substrate is exposed to the air, it will quickly rust. In addition, high temperature environments will also accelerate corrosion reactions, especially in high temperature and high humidity environments, the life of tinplate will be significantly shortened.

Therefore, tinplate products are usually recommended to be stored in a dry, moderately heated environment to reduce their contact with moisture and corrosive gases and extend their service life.

Chemical erosion

Tinplate products are often exposed to various chemicals during use. Certain acidic or alkaline chemicals can accelerate the corrosion of tinplate, especially when the coating or tin layer is damaged. The steel substrate is directly exposed to these chemicals and will quickly oxidize and corrode. For example, if a tinplate can is filled with acidic foods such as tomatoes or lemons, the corrosion resistance of the can will be tested, and long-term storage may cause corrosion inside the can.

In order to cope with this situation, manufacturers usually choose different coating and lining materials according to the nature of the contents to prevent chemicals from corroding the tinplate, thereby extending the shelf life of the product.

Physical wear and external damage

Tinplate products may be subjected to physical impact, wear or scratches during transportation, storage and use. Once the protective coating or tin layer on the surface is damaged, the metal substrate will be directly exposed to air and corrosive substances, which will quickly accelerate the corrosion process. Therefore, in actual use, how to properly handle and store tinplate products to avoid physical damage to their surface is also an important factor in extending their shelf life.

What is the impact of storage conditions on the shelf life of tinplate products?

The quality of storage conditions also has a direct impact on the shelf life of tinplate products. Reasonable storage conditions can effectively extend the life of tinplate products, while poor storage environment may shorten their shelf life.

Ventilation and dry environment

Storage of tinplate products should avoid humid environments, because moisture is one of the main factors causing tinplate corrosion. Keeping the storage area ventilated and dry can effectively reduce the contact between moisture in the air and the tinplate surface, thereby reducing the risk of corrosion. In addition, during storage, tinplate products should be avoided from being stacked directly on the ground, especially on cement floors or areas where water may accumulate, to prevent moisture from the ground from invading tinplate products.

Avoid direct sunlight

Long-term exposure of tinplate products to sunlight, especially in high temperature environments, may accelerate the aging of the coating and the oxidation of the tin layer. This will not only affect the appearance of the product, but also reduce its anti-corrosion performance. Therefore, tinplate products should be stored away from direct sunlight, especially when stored outdoors. It is recommended to use a sunshade or place them in a cool place.

Reasonable stacking method

When storing a large number of tinplate products, the stacking method is also an issue that needs attention. Unreasonable stacking may cause excessive pressure on the lower layer of products, resulting in deformation or coating damage. Therefore, reasonable stacking height and method can not only ensure the appearance integrity of the products, but also reduce the risk of corrosion caused by physical damage.

What is the shelf life of tinplate products?

In summary, there is no fixed answer to the shelf life of tinplate products. Its life span is affected by many factors such as material properties, manufacturing process, use environment and storage conditions. Under ideal conditions, the life span of tinplate products can reach decades or even longer, but in harsh environments, its life span may be greatly shortened.

Generally speaking, for conventional food cans and beverage packaging, the shelf life of tinplate products is usually around 3-5 years, depending on the nature of the contents. For some special-purpose tinplate products, such as chemical barrels or tool boxes, the service life can reach more than 10 years.