With the increasing global awareness of environmental protection, various industries have gradually realized the importance of sustainable development and environmental protection, especially in the field of packaging. Metal packaging, as a common form of packaging, is widely used because of its sturdy and durable characteristics. Among them, tinplate (also known as tin-plated thin steel plate) occupies an important position in metal packaging materials due to its unique performance and environmental advantages.

This article will explore in depth why tin plate sheet is an environmentally friendly material, from its recyclability, durability, environmental impact during production, and its role in reducing resource consumption.

Why is tinplate environmentally friendly?

1. Recyclability of tinplate

2. Durability and reusability of tinplate

3. Tinplate has less environmental impact during production

4. Advantages of tinplate in reducing resource consumption

Recyclability of tinplate

The environmental friendliness of tinplate is first reflected in its excellent recyclability. Metal materials generally have good reuse potential, and tinplate, as a metal material, is particularly recyclable.

1. Efficient recycling cycle

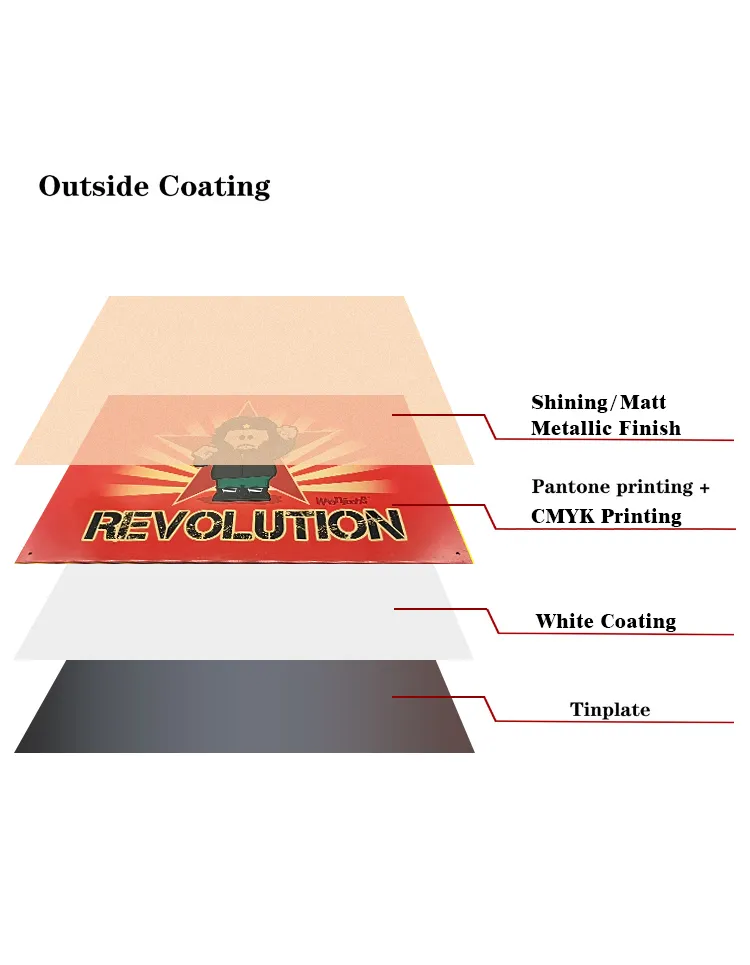

Tinplate is a highly recyclable material and can be recycled indefinitely without losing its original properties. Unlike plastics or composite materials, tinplate does not degrade in material properties during the recycling process, that is, no matter how many times it is recycled, tin plate sheet can still maintain its original strength, toughness and corrosion resistance. This infinite recycling feature makes tinplate an important part of sustainable packaging materials.

2. Simple recycling process

The recycling process of tin plate sheet is relatively simple and efficient. After being discarded, tin plate sheet can be easily separated from other garbage by magnetic separation. Since tin plate sheet is ferromagnetic, it can be quickly extracted from mixed waste using magnets during waste recycling. This not only improves the efficiency of recycling, but also reduces the cost of recycling, making tinplate an economically viable and environmentally friendly packaging material.

3. High recycling rate

Globally, the recycling rate of tin plate sheet is generally at a high level. For example, in some developed countries, the recycling rate of tinplate can reach more than 80%. This means that most of the discarded tinplate containers and packaging can be re-entered into the production process, avoiding the waste of resources. In addition, the high recycling rate means that the demand for new raw materials can be reduced, thereby reducing the negative impact of metal mining on the environment.

Durability and reusability of tinplate

In addition to recyclability, the durability of tinplate is also one of its environmental advantages. Compared with other packaging materials, the sturdiness and durability of tinplate enable it to be reused for a long time, thus reducing the consumption of packaging materials and the generation of waste.

1. Corrosion resistance and long life

The surface of tinplate is coated with a layer of tin, which not only enhances its aesthetics, but also gives tinplate excellent corrosion resistance. This allows tinplate to maintain a long service life even when used in humid or acidic and alkaline environments. For example, in food and beverage packaging, tinplate can protect the contents from the influence of the external environment for a long time, extend the shelf life of the product, and reduce the waste caused by product damage.

2. Reusability

The sturdiness of tinplate containers allows them to be used not only as disposable packaging, but also for multiple times. For example, after the cans and storage boxes made of tinplate are used, users can use them as household storage boxes or other purposes. In this way, the service life of tinplate containers is extended, indirectly reducing the demand for other disposable packaging materials, thereby reducing the generation of waste.

Tinplate production process has less environmental impact

Although metal production usually involves high energy consumption, the production process of tinplate has its unique advantages in environmental protection. Modern tinplate production technology has reduced the impact on the environment in many ways, including reducing energy consumption, wastewater treatment, and exhaust emission control.

1. Energy-saving production process

The production process of tinplate mainly includes the processing of steel plates and the plating of tin layers. In this process, although the metallurgical process consumes a lot of energy, with the advancement of technology, more efficient and energy-saving technologies have gradually been adopted in the production process. For example, by improving the smelting and rolling processes, the unit energy consumption of tinplate production has been greatly reduced, reducing carbon emissions. In addition, modern factory equipment is more optimized in energy use, and the widespread application of waste heat recovery technology has also reduced energy waste in the production process.

2. Control and treatment of wastewater and waste gas

During the tinning process, certain wastewater and waste gas may be generated, especially wastewater containing heavy metals needs to be strictly treated. However, modern tinplate production enterprises have adopted advanced wastewater treatment systems to effectively remove harmful substances in wastewater through physical, chemical, biological and other methods to ensure that the discharged water quality meets environmental protection standards. At the same time, the emission of waste gas is also strictly controlled, and the factory is equipped with effective filtering and adsorption equipment to reduce air pollution. These measures make the production process of tinplate more compliant in terms of environmental protection.

3. Reduce the waste of raw materials

In the production process of tinplate, the utilization rate of raw materials is high and the waste is less. Since the shape and size of steel materials can be highly accurately controlled through processes such as rolling and shearing during processing, the waste of materials is reduced. In addition, the metal waste generated in the production process can be directly recycled and reused in the production process. This closed-loop production method effectively reduces the burden on the environment.

Advantages of tinplate in reducing resource consumption

Against the background of increasingly tight resources, reducing the consumption of natural resources has become a focus of attention in various industries. As a metal packaging material, tin plate sheet has obvious advantages in terms of resource efficiency and material sustainability.

1. Saving mineral resources

Due to the high recycling rate of tin plate sheet, its demand for new raw materials is greatly reduced. Compared with other packaging materials, such as plastics, which rely on petrochemical products for production, tin plate sheet can reduce the demand for iron ore mining through recycling. This not only helps save limited mineral resources, but also reduces the damage to the ecological environment during the mining process.

2. Lightweight design reduces material consumption

With the advancement of production technology, lightweight design of tinplate materials has become a reality. Despite the weight reduction, tinplate still maintains its excellent mechanical properties. By reducing the thickness of the material, manufacturers can reduce metal consumption without affecting the strength and function of the packaging. This lightweight strategy helps to reduce resource usage while reducing energy consumption during transportation.

3. Reduce product waste

The strength and corrosion resistance of tinplate not only make it an advantage in the market as a packaging material, but more importantly, it can effectively protect the products in the package. Whether it is food, beverage or chemical products, tinplate packaging can prevent the influence of the external environment and ensure that the product remains intact and safe during transportation, storage and use. By reducing product damage, tinplate indirectly reduces product waste, thereby reducing resource consumption and environmental burden.

The positive impact of tinplate's environmental protection on society

As an environmentally friendly material, the widespread use of tinplate not only has a positive impact on the environment, but also promotes the sustainable development of society.

1. Encourage circular economy

The high recycling rate and reusability of tin plate sheet are in line with the concept of circular economy. By promoting the recycling of resources, it reduces dependence on natural resources and reduces the generation of waste. The use of tin plate sheet packaging has promoted the whole society's awareness of sustainable consumption and production patterns and contributed to the development of circular economy.

2. Reduce landfill and marine pollution

Plastic packaging materials are difficult to decompose in the natural environment and exist in landfills and oceans for a long time, causing serious harm to the ecosystem. As a recyclable metal material, tinplate's waste is not easy to enter the natural environment, and the recycling process is simple and efficient. By reducing the use of non-degradable materials such as plastic, tin plate sheet helps reduce the burden on landfills and plastic pollution in the oceans.