As the main material of food packaging cans, tinplate has been widely used in canned food, beverages, condiments and other packaging due to its superior corrosion resistance and sealing performance. In these food packaging cans, tinplate not only plays the role of protecting food safety and extending shelf life, but also guarantees the mechanical strength of the packaging to a certain extent. In order to meet these functional requirements, the thickness of tinplate has become a key technical indicator. So, how thick is the tinplate on food packaging cans?

This article will discuss in detail the specific meaning of tinplate thickness, the standard thickness range, the factors affecting the thickness selection, and its impact on the performance of food packaging cans.

What is tinplate thickness?

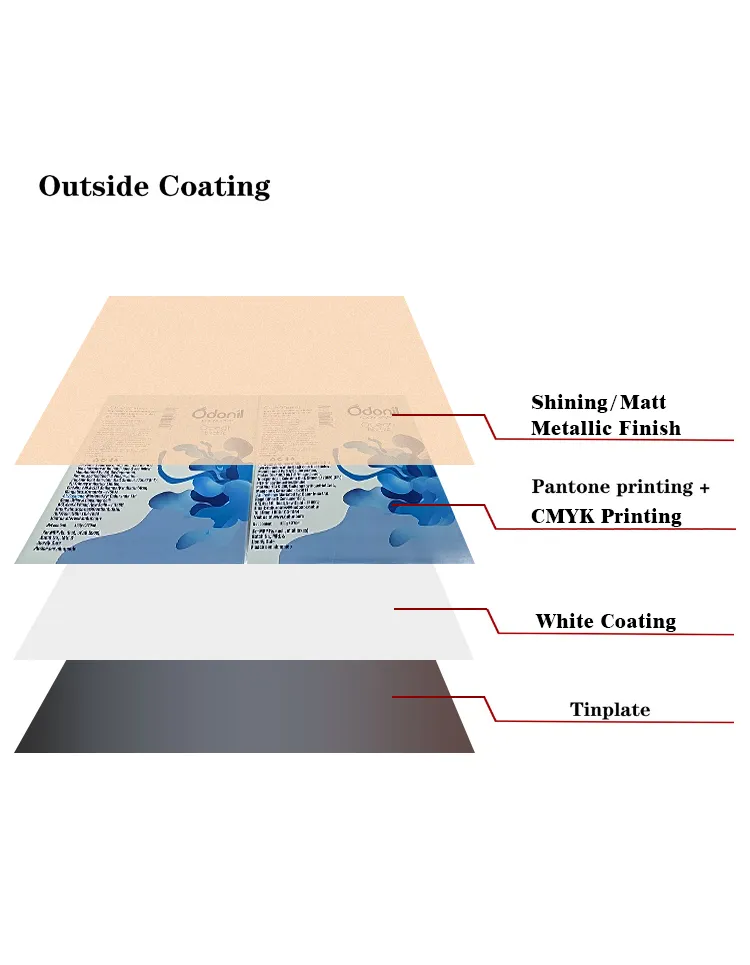

Before discussing the thickness of tinplate, it is necessary to first clarify the structure and composition of tinplate. The core of tinplate is a layer of low-carbon steel plate, which is coated with tin on both sides to enhance its corrosion resistance. Therefore, the thickness of tinplate usually refers to the thickness of the base material of the steel plate, not simply the thickness of the tin coating.

Although the tin coating plays a key role in protecting tinplate from external corrosion, its thickness is relatively thin, usually measured in microns. In contrast, the thickness of the substrate determines the strength, durability and processing performance of the packaging can. Therefore, when discussing the thickness of tinplate, people often focus more on the thickness of the steel plate itself, and the thickness of the tin layer is considered as additional information.

Why is the thickness of tinplate so important for food packaging cans?

How does thickness affect the corrosion resistance of food packaging cans?

Food packaging cans are exposed to various corrosion risks during production and use, especially foods with high salt, acid or alkalinity. In this case, the thickness of tinplate is directly related to its corrosion resistance. Usually, the tin layer on the surface of tinplate can effectively prevent oxygen, moisture, etc. from entering the can body and delay the corrosion process. However, if the thickness of the tinplate is not enough, once the tin layer is damaged or scratched, the iron substrate is susceptible to corrosion. Therefore, in order to ensure food safety and extend the service life of the packaging can, the thickness of the tinplate must meet certain standards to provide adequate protection.

What is the relationship between thickness and the sealing of the can body?

Sealing is an important indicator of food packaging cans, which directly affects the freshness of food. The thickness of tinplate determines the strength and sealing effect of the can body. Thicker tinplate can provide stronger pressure resistance and bending resistance, ensuring that the can body is not easily deformed during processes such as high-pressure sealing or heating sterilization, thereby ensuring sealing. In addition, whether the food packaging can is easy to reclose after opening is also related to the thickness of the tinplate. In production, choosing a suitable thickness of tinplate helps to ensure the stability of the can body and keep the canned food fresh during the shelf life.

What is the thickness of tinplate used in common food packaging cans?

Is the thickness of tinplate the same for various types of food cans?

The thickness of tinplate for food packaging cans is not uniform, but varies according to the type of food, the shape of the packaging can and the physical properties of the contents. For example, the packaging of acidic food cans such as jam and ketchup often requires thicker tinplate to resist the erosion of acidic components. Generally speaking, the thickness of tinplate for such food packaging cans is about 0.20 mm to 0.30 mm. For ordinary beverage cans, candy boxes and other food packaging cans that do not contain acidic substances or have less corrosive ingredients, the thickness of the tinplate can be slightly thinner, about 0.15 mm to 0.20 mm. Through the demand analysis of different types of food, choosing the right thickness can not only improve the protective performance of the tinplate can, but also effectively control the production cost.

Do special food packaging cans require thicker tinplate?

For some special foods, such as those containing highly corrosive chemical ingredients or foods with a long shelf life, it may be necessary to use thicker tinplate. These foods may cause long-term corrosion to the can body, so thicker tinplate can provide more effective protection and extend the shelf life of the food. In addition, for large food packaging cans, such as large cans of more than 5 liters, the can body area is large and the pressure is high. It is safer and more reliable to use tinplate materials with a thickness of more than 0.25 mm.

How to measure the thickness of tinplate?

What are the thickness measurement methods?

The thickness of tinplate can be measured by a variety of methods to ensure that the materials used in production meet the standards. The most commonly used measurement methods include vernier caliper, micrometer measurement and ultrasonic thickness measurement.

● Vernier caliper method: Vernier caliper is a high-precision measuring tool that can quickly and easily measure the thickness of tinplate. However, vernier calipers are usually used for relatively flat surface measurements and are suitable for measuring small-sized tinplate sheets.

● Micrometer measurement method: Micrometers are more accurate and are usually used for high-precision measurements. They can achieve micron-level thickness measurements, so they are suitable for measuring a smaller range of tinplate sheets, especially when the thickness tolerance is strictly controlled.

● Ultrasonic thickness measurement method: This measurement method uses the propagation speed of sound waves in the material to determine the thickness, and is suitable for measurement without damaging the tinplate surface. Ultrasonic measurement is a non-contact measurement that can avoid secondary effects on the material caused by the measuring instrument, so it is widely used in tinplate thickness control.

Will the measurement result be affected by external factors?

The measurement result of tinplate thickness may be affected by some external factors. Temperature, humidity and whether the material surface is smooth will have a certain impact on the measurement result. Especially when using ultrasonic measurement, temperature changes in the measurement environment may affect the propagation speed of sound waves, resulting in deviations in thickness measurement results. Therefore, in the actual production process, environmental conditions such as temperature and humidity need to be controlled within a certain range during measurement to ensure the accuracy of the measurement data.

Does the thickness of tinplate affect printing and processing?

What is the effect of thickness on printing quality?

Tinplate packaging cans usually need to be printed to meet the needs of aesthetics and marketing. The thickness of tinplate has a direct impact on printing quality, especially materials with uneven thickness or thinness are prone to problems during printing. Thicker tinplate materials are more stable during printing, reducing the possibility of bending and deformation, and keeping the printed pattern accurate and uniform. In addition, tinplate with sufficient thickness is not easy to deform under high temperature or high pressure conditions, which can ensure that the printed pattern does not distort and fade, and improve the overall aesthetics of the packaging.

Does thickness affect molding processing?

The molding process of tinplate packaging cans includes cutting, folding, curling and sealing. Tinplate with inappropriate thickness will affect the smooth progress of the molding process. Thicker tinplate materials are more stable during folding and curling, and are not prone to cracks or breakage. However, too thick tinplate will increase the difficulty of processing, easily lead to increased tool wear, and even affect the sealing after forming. Relatively speaking, although thinner tinplate materials are easier to handle during forming, their ability to withstand external pressure is limited, which may lead to a decrease in the pressure resistance of the finished product. Therefore, choosing the right thickness not only helps the efficiency of the forming process, but also ensures the strength and durability of the packaging can.

How do tinplate materials of different thicknesses perform in use?

Does thickness affect durability?

Tinplate packaging cans need to withstand various external forces and environmental changes during use. Thicker tinplate materials have higher durability and can maintain the integrity of the can body during transportation and storage, avoiding deformation or rupture due to uneven force. For food cans that need to be stored for a long time, thicker tinplate materials can effectively extend the service life of the packaging, thereby reducing the risk of food spoilage. In addition, thicker materials are more resistant to wear during frequent handling.

Is there an optimal solution with moderate thickness?

The thickness of tinplate packaging cans is not the thicker the better, but needs to be considered comprehensively according to the type of food, storage environment and can size. Generally speaking, the thickness of tinplate for common food cans is about 0.20 mm to 0.30 mm, which is regarded as the "golden thickness" for food can packaging. This thickness can not only ensure sufficient corrosion resistance and pressure resistance, but also facilitate processing and molding without excessively increasing production costs. Therefore, for most food cans, choosing tinplate with moderate thickness can achieve the best balance between cost and function.