As a commonly used food packaging material, tinplate is widely used in the packaging of foods such as cans, beverages and candies due to its good mechanical properties, corrosion resistance and printing effect. However, in order to improve the durability and food safety of tinplate, whether electrolytic treatment is required during the production process has become a key issue. Electrolytic treatment can not only enhance the corrosion resistance of tinplate, but also improve its surface finish and adhesion. So, does tinplate used for food packaging need electrolytic treatment? What factors will affect this decision? This article will explore the relevant issues in detail.

What is electrolytic treatment? Why is it closely related to tinplate?

What is electrolytic treatment?

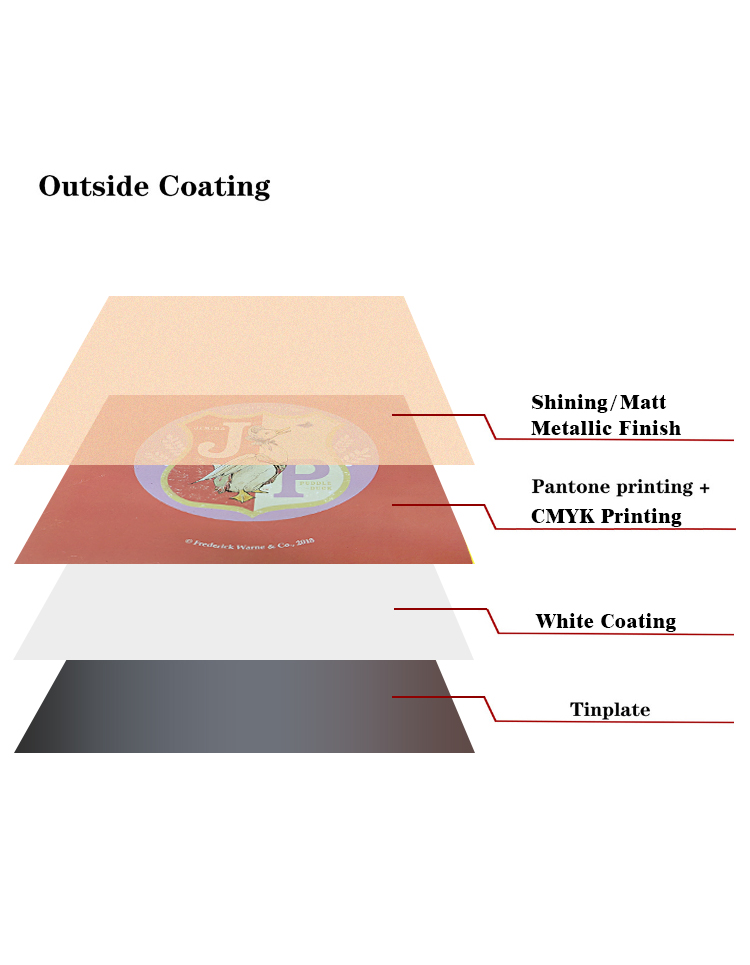

Electrolytic treatment is a process that uses electrochemical methods to modify metal materials. In the production of tinplate, electrolytic treatment usually refers to the electroplating of a layer of tin or other metal protective layer on the surface of the iron substrate. This protective layer not only enhances the corrosion resistance of tinplate, but also gives it higher gloss and surface smoothness, making it more suitable for food packaging applications. The core of electrolytic treatment is to induce metal ion migration through electric current, so that it is evenly deposited on the surface of the substrate, thus forming a dense protective film.

Why do food packaging cans have special requirements for electrolytic treatment?

Food packaging cans have very strict requirements on materials, especially their corrosion resistance and food contact safety. Acidic or alkaline components in food may cause corrosion to the metal surface, while the surface of tinplate after electrolytic treatment has stronger chemical corrosion resistance, which can effectively prevent direct contact between food and metal. In addition, the surface of tinplate after electrolytic treatment is smoother, which is convenient for subsequent printing and processing, making the packaging can more visually beautiful and more functionally reliable.

Do all tinplates for food packaging need electrolytic treatment?

Is electrolytic treatment suitable for all types of food packaging?

Not all food packaging cans must use electrolytically treated tinplate. Whether electrolytic treatment is needed depends mainly on the chemical properties of the food and the environment in which the packaging can is used. For example, for foods with strong acidity (such as ketchup, lemon juice, etc.), electrolytically treated tinplate is the first choice because of its stronger anti-corrosion performance. For some dry, non-acidic foods (such as biscuits and candies), their packaging cans may have lower requirements for corrosion resistance, and tinplate that has not been electrolytically treated can also meet the requirements.

How much impact does electrolytic treatment have on food safety?

Electrolytic treatment is directly related to food safety. When tinplate that has not been electrolytically treated is in contact with food for a long time, it may release iron ions due to insufficient surface protection, causing food deterioration or affecting human health. The surface of the electrolytically treated tinplate is covered with a dense layer of tin or other metal layer, which can effectively isolate the contact between food and the iron substrate and prevent heavy metal leakage. Therefore, electrolytic treatment is usually essential for packaging cans that need to directly contact food.

What are the improvements in the performance of tinplate by electrolytic treatment?

How to enhance the corrosion resistance of tinplate?

Electrolytic treatment significantly improves its corrosion resistance by uniformly depositing a metal coating (such as tin or chromium) on the surface of tinplate. This coating can effectively block the erosion of oxygen, moisture and other corrosive media on the iron substrate, especially in acidic or high humidity environments, the anti-corrosion effect is particularly significant. In addition, electrolytic treatment can also repair minor defects on the surface of tinplate that may occur during the production process, making its protective performance more stable.

Does electrolytic treatment affect the mechanical properties of tinplate?

In addition to corrosion resistance, electrolytic treatment can also improve the mechanical properties of tinplate to a certain extent. The surface of electrolytically treated tinplate is smoother, reducing scratches and cracks caused by friction during processing, thereby improving the overall durability of the packaging can. In addition, electrolytic treatment can also increase the flexibility of tinplate, making it less likely to crack during molding.

In what cases must tinplate be electrolytically treated?

Does the packaging of acidic foods necessarily require electrolytic treatment?

The packaging of acidic foods is one of the typical scenarios for the application of tinplate electrolytic treatment. Since acidic foods are prone to chemical reactions with metals, tinplate that has not been electrolytically treated may release metal ions due to corrosion, which in turn affects the safety and taste of the food. Therefore, when packaging acidic foods, it is usually necessary to choose electrolytically treated tinplate to ensure that the coating on its surface has sufficient protective capabilities.

What are the requirements for electrolytic treatment in high humidity storage environments?

In high humidity environments, the corrosion resistance of tinplate is crucial. Increased humidity accelerates the metal oxidation process, making the surface of the packaging can more susceptible to rust. In this case, the uniform coating provided by electrolytic treatment can act as a good barrier, effectively preventing moisture from penetrating into the iron substrate and protecting the food from contamination. Therefore, electrolytically treated tinplate is a safer and more reliable choice for food packaging cans that are used for refrigerated food or need to be stored for a long time.

Does electrolytic treatment affect the printing and processing of tinplate?

Does it affect the printing quality?

The surface finish of electrolytically treated tinplate is higher, providing a good adhesion foundation for printing ink. When printing, the ink can be evenly distributed on the tinplate surface, reducing color difference and de-inking caused by surface roughness. In addition, electrolytic treatment can also improve the durability of the printed pattern, ensuring that the food packaging cans always remain beautiful during use.

Does electrolytic treatment improve processing efficiency?

Electrolytic treatment can also improve the processing performance of tinplate. The uniformity of the surface coating makes tinplate more stable in forming processes such as bending, stamping and curling, reducing the risk of cracks or breakage caused by stress concentration. Especially when processing packaging cans with complex shapes, electrolytically treated tinplate can significantly improve production efficiency and reduce the defective rate.