Tinplate, that is, tin-plated thin steel sheet, as a common metal material in industrial production and daily life, is widely used in packaging containers in the food, chemical and other industries. Due to its good corrosion resistance and processing performance, tin plate products are popular in the market. However, as the service life of these products expires, how to deal with waste tinplate products has become a problem worthy of attention.

Can tinplate products be recycled? The answer is yes, and its recycling is of great significance in resource conservation and environmental protection.

What are the basic composition and characteristics of tin plate products?

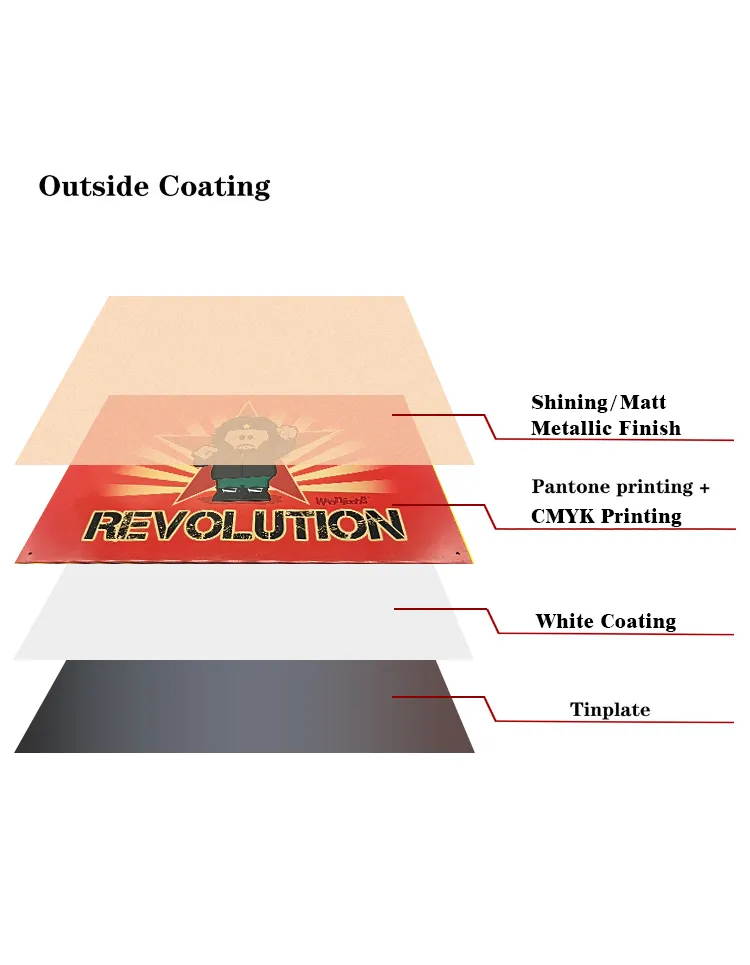

Before understanding whether tin plate products can be recycled, you first need to understand the basic composition and characteristics of tinplate. Tinplate is made of steel as the base, with a thin layer of tin on the surface. This metal combination gives tin plate products unique properties, with both the strength of steel and the corrosion resistance of tin.

1. Steel base: The core material of tinplate sheet is low carbon steel or mild steel, which has good strength and ductility. This steel provides basic mechanical support for tinplate sheet, making it suitable for various stamping, stretching and other processing techniques.

2. Tin plating: The tin plating on the surface of tinplate sheet is usually very thin, with a thickness of only a few microns to more than ten microns. The main function of the tin layer is to prevent the steel matrix from contacting with air and water, and to prevent rust. At the same time, the tin layer also gives tin plate products better chemical corrosion resistance, which makes it an ideal choice for food packaging materials.

Can tinplate products be recycled?

As a metal material, the recycling value of tin plate products cannot be ignored. Compared with other scrap metal materials, the recycling process of tinplate products is relatively simple and has significant environmental benefits.

The limited nature of metal resources and the importance of recycling

The metal resources on the earth, especially iron ore and tin ore resources, are limited. Although the tin layer of tinplate products is very thin, tin is a scarce and important metal that is widely used in electronics, chemicals, automobiles and other fields. Therefore, recycling and reusing scrap tinplate products can not only reduce the over-exploitation of primary resources, but also effectively reduce damage to the environment.

At the same time, steel production is a highly energy-intensive process, and recycling steel can significantly reduce energy consumption. According to statistics, the production of one ton of recycled steel only consumes 25% of the energy required for the production of primary steel. Therefore, the recycling of tinplate products has a positive effect on saving energy and reducing carbon emissions.

Analysis of the recyclability of tinplate products

From the perspective of material composition, tin plate products can be completely recycled. The recycling of the steel matrix is no different from ordinary steel, and can be reprocessed into new steel products through smelting. Although the tin layer on the surface is thin, it also has recycling value. During the recycling process, tin and steel can be separated by physical and chemical means to achieve the reuse of tin.

From a technical point of view, the current metal recycling technology is mature enough to efficiently process waste tin plate products. Recycling plants usually use processes such as magnetic separation and smelting to separate the different components in tin plate products to achieve the dual use of steel and tin. Therefore, the recycling of tinplate products is not only feasible in theory, but has long become a mature industrial process in actual operation.

What is the recycling process of tinplate products?

The recycling of tin plate products mainly includes collection, separation, treatment and reuse. The following is a detailed analysis of the recycling process:

Collection

The recycling of tinplate products first requires the collection of discarded tinplate products from the source. In daily life, tinplate sheets mainly exist in the form of food cans, beverage cans and chemical containers. Therefore, the collection of waste tinplate products can be carried out through various channels such as scrap metal recycling stations and garbage sorting systems.

Modern waste management systems are already able to perform preliminary classification of metal products to ensure that tin plate products can be effectively separated from other wastes. Due to the magnetic properties of tinplate products, magnetic separation equipment can be used to separate iron-based materials from mixed waste. This step not only improves recycling efficiency, but also reduces the impact on subsequent processing links.

Separation

One of the difficulties in recycling tinplate products is the separation of the tin layer on its surface from the steel matrix. Common separation techniques include the following:

● Chemical separation method: The tin layer on the surface of the tinplate product is dissolved by using an acidic or alkaline solution to peel off the tin from the steel matrix. This method is easy to operate and suitable for large-scale recycling, but the chemical waste liquid generated needs to be strictly treated to avoid polluting the environment.

● Thermal separation method: The waste tin plate products are heated to a high temperature to melt the tin layer and evaporate or separate it from the steel matrix. This method is highly efficient and does not produce chemical pollutants. However, the thermal separation method has high requirements for equipment and consumes a lot of energy.

● Electrolytic separation method: The tin plate products are placed in an electrolyte and the tin layer is stripped from the steel matrix through an electrochemical reaction. This method is delicate and can recover tin to the greatest extent, but it takes a long time and requires a high investment in equipment. It is suitable for high-value metal recycling occasions.

Smelting treatment

After the tin layer and the steel matrix are separated, the next step is to smelt these metals. The steel part can be directly put into the steel smelting furnace and re-smelted into steel products. During the smelting process, the addition of appropriate alloying elements can also adjust the performance of the steel to meet the needs of different industrial fields.

The recovery of tin is relatively complicated. Due to the thin tin layer, the recovery amount is relatively small. Recycled tin usually exists in the form of tin-containing waste liquid or waste slag, and needs to be further purified to obtain high-purity tin. The purified tin can be reused in electroplating, electronic component manufacturing and other fields to give full play to its economic value.

Reuse

Both processed steel and tin can be reused to make new products. Steel can be used in construction, machinery manufacturing and other fields, while recycled tin can be used for solder in the electronics industry, plating materials in the electroplating industry, etc. Through this recycling, tinplate products have achieved the transformation from waste to resources, which not only reduces resource waste but also reduces the environmental burden.

What are the environmental benefits of recycling tin plate products?

The recycling of tinplate products not only has significant economic benefits, but also brings great environmental benefits. First of all, recycling reduces dependence on primary metal resources and reduces the damage to the natural environment during mining and smelting. The mining process is usually accompanied by a lot of ecological damage, soil erosion and water pollution, and these problems can be effectively avoided by recycling metal resources.

Secondly, less waste is generated during the recycling of tin plate products. Most waste tinplate products can be efficiently reused through physical separation, smelting and other means during the recycling process, reducing the amount of waste that eventually enters the landfill. This has a positive effect on reducing the pressure on the waste disposal system and reducing the occupation of land resources by waste landfill.

Finally, recycling tinplate products can also effectively reduce greenhouse gas emissions. Compared with the production of new steel and new tin, the energy required for recycling is greatly reduced, thereby reducing the emission of greenhouse gases such as carbon dioxide. This is also of great significance for the mitigation of global climate change.

What are the challenges in the recycling of tinplate products?

Although the recycling of tin plate products has broad prospects, there are still some challenges in the actual operation process.

● Technical difficulties in the separation process: The effective separation of the tin layer is one of the key links in the recycling of tin plate products. How to reduce energy consumption and pollution while separating efficiently is a difficulty in technical research and development.

● Recycling cost issues: Although the recycling of tinplate products can bring significant environmental benefits, factors such as equipment investment and labor costs in the recycling process affect its economic feasibility. Therefore, how to further reduce the recycling cost technically is the focus of future development.

● Public awareness and participation: Tin plate products are widely used in daily life. The public's awareness of tinplate product recycling directly affects the efficiency of the recycling system. Improving the public's environmental awareness and promoting the improvement of garbage classification and metal recycling systems are important means to increase the recycling rate of tin plate products.